New research conducted at the Korea Institute of Science and Technology (KIST) lead to the evolution of a flame-retardant carbon-fibre-reinforced composite material (CFRP). This plastic molecule is synthesized with the help of tannic acid. Tannic acid is a compound that gets converted into carbon when burnt and is found in abundance, as it is usually synthesized by plants. The research team also revealed the recycling process of the plastic. It is Eco friendly and recycles up to 99% within a couple of minutes. Carbon-Fiber-Reinforced plastic is an extremely sturdy and light fibre-reinforced plastic.

What is Carbon Fiber Reinforced Plastic?

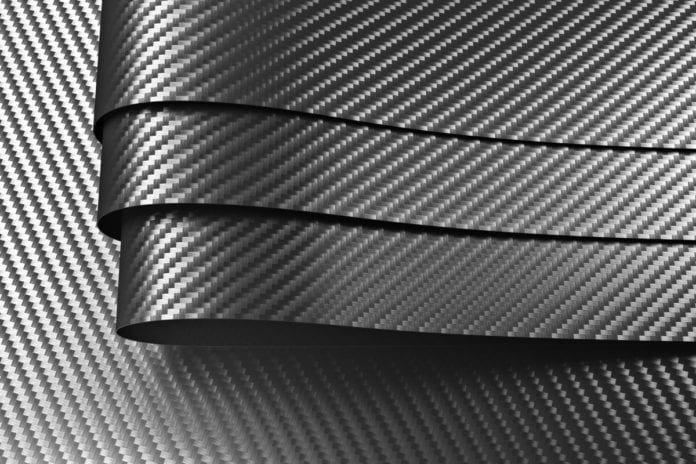

Carbon Fibre Reinforced Plastics are commonly used in aerospace structures, superstructures of ships, civil engineering, and in a lot of consumer and technical applications. These materials are composite in nature (i.e. contains a reinforcement and a matrix.) Carbon fibre is the reinforcement of a polymer which provides strength and the matrix is the epoxy that holds the reinforcements together. The strength and properties of CFRPs vary due to the layout and percentage of the reinforcements used. They are also known as graphite fibre-reinforced polymer.

Head researcher, Dr Yong Chae Jung said, “We have created a composite material with an expanded range of application that is a dramatic improvement over conventional carbon-fibre-reinforced plastic in terms of flame-retardancy, mechanical rigidity, and recyclability.” These improved traits are significant in that they determine the range of application of said composite material. He further exclaimed, “We will be reviewing the structure of this composite material to achieve even further improved properties and to further expand the range of its application.”

Why was Carbon Fiber Reinforced Plastic banned in 1980s?

Another major problem was to make the Carbon Fiber Reinforced Plastic flame resistant. Conventionally, to make them a fire-retardant, halogens were used. But later, the use of halogens was limited and ultimately banned as they produced noxious fumes when carbonized. The epoxy resin that is made from tannic acid is flameproof and it restores the property of a fire-retardant while being safe for the environment. This means that the toxic substances generated when recycling conventional CFRPs will no longer be a problem.

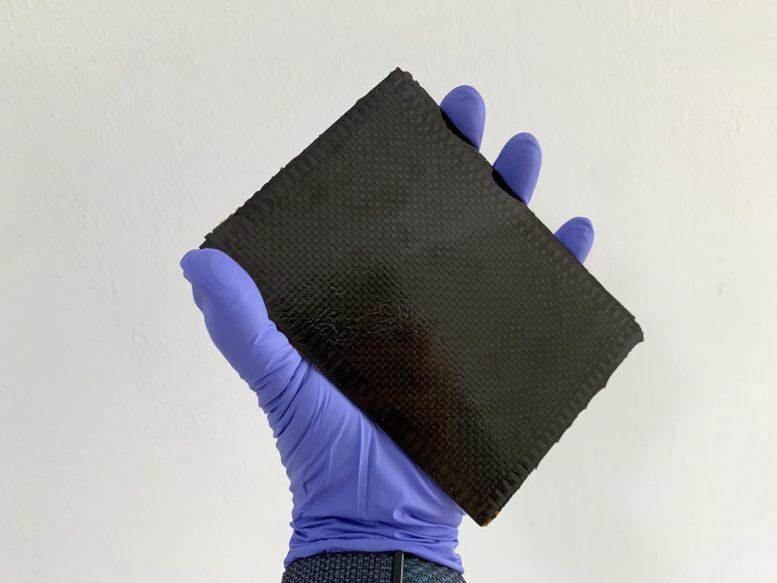

By producing epoxy resin from tannic acid and mixing it into carbon fibre, a CFRP was developed that was strong and eco-friendly. By dissolving CFRP in water in a supercritical fluid state—i.e., temperature and pressure over a set level—over 99% of the CFRP could be recovered without reduced carbon fibre performance.

It was observed that epoxy resin when dissolved, produced a substance called “carbon dots,” which can be used as an electronic material for Optronics, Sensing, Bio-imaging, etc. Unlike the conventional method of recycling which burns up epoxy resin leaving only the incomplete carbon fibre to be recycled, this new method of recycling enables the recycling of all components of a composite material.

The research, published by the Ministry of Science and ICT, was conducted at the Institutional Research Program of the Korea Institute of Science and Technology. This polymer is 4 times lighter than steel but over 10 times stronger than it. It is a potent combo of strength and low weight.

Further Reading: